NVT DAS

Advanced System for Testing and Monitoring Rotating Machinery

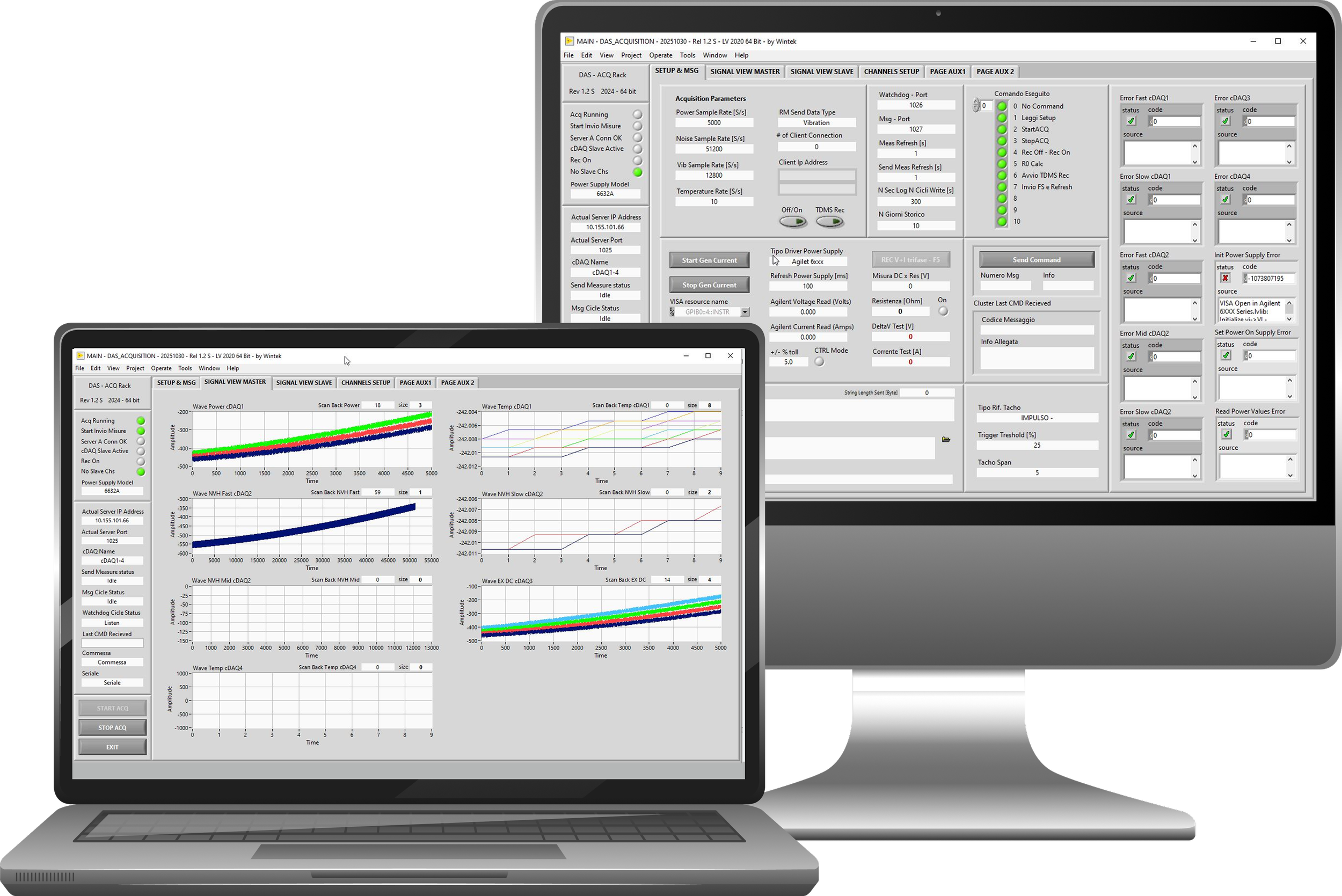

The NVT DAS system is Wintek’s dedicated solution for testing, diagnostics, and performance evaluation of rotating machinery, including pumps, compressors, fans, and turbomachinery.

Built on NI cDAQ/cRIO distributed hardware and a proprietary Real-Time software engine, it delivers precision, reliability, and scalability for any industrial testing requirement.

-

NVT DAS is designed for high-complexity testing applications requiring:

High-speed dynamic data acquisition

Real-time signal processing

Advanced vibration and thermodynamic analysis

Centralized management of large channel counts

Reliable and traceable test data

Its modular structure enables both portable and distributed configurations, making it ideal for field activities as well as advanced test rooms.

-

Supported Platforms

NI cDAQ systems

NI cRIO systems

NI C-Series modules for real-time acquisition

Supported Signal Types

Accelerometers

Displacement transducers

Eddy current probes

Key-Phasor sensors

Thermocouples, Pt100

Industrial 4–20 mA signals (flow, pressure, power, etc.)

Channel Scalability

Supports 350+ channels directly through the Real-Time engine

-

This section merges channel management, instrumentation setup, and industrial connectivity—everything that governs the interaction between NVT DAS and your test environment.

Instrumentation & DUT Configuration

Full definition of device-under-test parameters

Advanced configuration of each acquisition channel

Support for a wide range of measurement sensors

Automated tracking of calibration certificate expiration, with clear indication of non-compliant transducers

Seamless Integration with Test Room Automation

Native connectivity with PLCs, test bench controllers, and automation systems through standard industrial protocols:

Modbus

OPC UA

CAN Bus

Ethernet/IP

This ensures complete synchronization between acquisition, automation logic, and test operations.

-

1. Portable Version

Designed for field diagnostics and rapid testing.

Stand-alone software

Works with one or multiple chassis

Immediate acquisition and processing

2. Distributed Version

Engineered for complex or multi-bench test rooms.

Multiple single- or multi-chassis acquisition units

Centralized data routing server

One or more HMI Viewer workstations

Full synchronization and coordinated test management

-

Computed Quantities

DC Level

RMS

True Peak

Peak-to-Peak

Vibration Analysis

FFT spectra with Overall value and the top 10 peaks per API 610

Order tracking analysis

Bearing orbits from eddy current probes (raw or order-based)

Thermodynamic Analysis

Integration of electric motor efficiency curves

Gearbox correction support

Certified fluid-property libraries (including actual Specific Gravity)

-

Real-Time Visualization

Fully customizable synoptic

Real-time dynamic and static plots

Historical and timeline-based parameter logging

Continuous Logging

Real-time logging of all computed metrics

Recording of RAW signals and FFT spectra for each dynamic channel

Integrated Post-Processing

Direct loading and analysis of recorded data

Automated advanced reporting for metrics, spectra, orbits, and trends

Additional Modules

The NVT-DAS EP module adds to the system the ability to acquire and analyze the electrical parameters of motors and industrial power systems, with support for three-phase, single-phase, and DC measurements, harmonic analysis, power quality evaluation, calculation of fundamental electrical quantities, and synchronization with mechanical and thermal signals.

👉 Discover the full module: NVT-DAS EP