NVA-RM

Advanced System for Dynamic and Acoustic Monitoring of Rotating Machinery

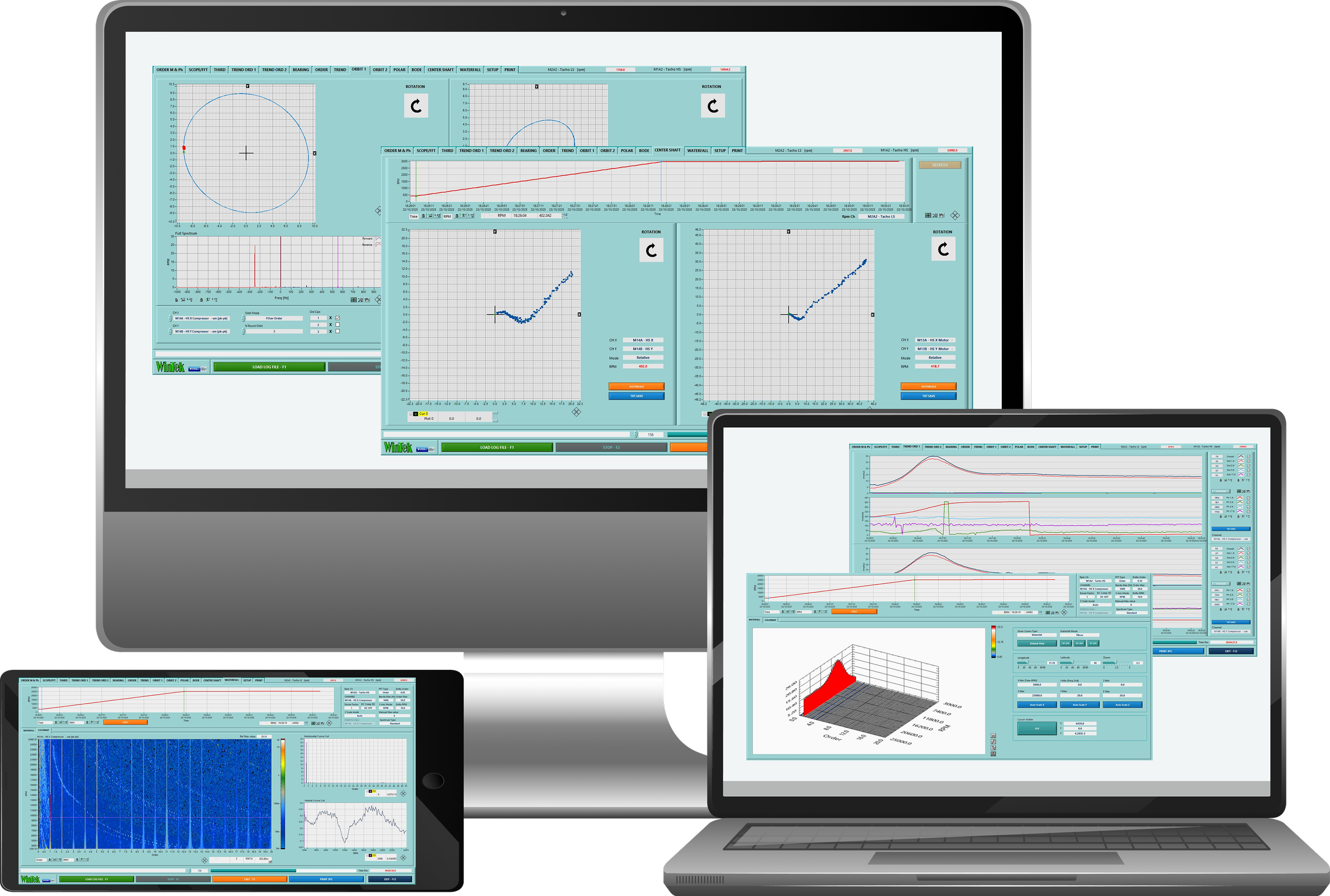

NVA-RM is WinTek’s dedicated solution for continuous monitoring, advanced dynamic analysis, and acoustic diagnostics of rotating machinery, including pumps, compressors, turbines, generators, alternators, and complex industrial rotating equipment.

A flexible and scalable system based on high-performance NI hardware platforms and a powerful Real-Time engine, designed to deliver accurate measurements, reliable diagnostics, and advanced analysis both in real-time and post-processing.

-

NVA-RM is engineered for condition monitoring, vibration diagnostics, and advanced acoustic analysis. The suite integrates:

High-frequency multi-sensor acquisition

Real-Time and post-process analysis

Advanced alarm and anomaly detection

Industrial integration for automated test environments

The system is suitable for test rooms, critical rotating assets, and industrial applications requiring maximum reliability and diagnostic depth.

-

Supported Platforms

NVA RM is compatible with several NI hardware families:

NI cDAQ multi-channel systems

NI cRIO Real-Time systems

NI PXI high-performance multi-channel systems

Supported Sensors

Depending on the chosen hardware configuration, NVA RM can manage virtually any industrial transducer, including:

Accelerometers

Velocimeters

Eddy current probes

Key-Phasor sensors

RTDs and Thermocouples

Strain-gage sensors, load cells, torsional sensors

Any extensometric-based transducer

Transducer and Channel Setup

A dedicated setup interface allows complete definition of:

Transducer characteristics

Scaling and engineering units

Filters, integrations, and conditioning

Acquisition and logging parameters

-

The system can send and receive metrics, calculated parameters, and alarms through:

CAN Bus

MODBUS

OPC UA

Alarm and warning states can also be managed via digital I/O, enabling immediate interaction with PLCs or supervisory systems.

-

Advanced monitoring functions include:

Configurable thresholds and limit values

Spectral masks for real-time anomaly recognition

Overall level monitoring on predefined frequency bands

A dedicated Real-Time Synoptic displays:

Overall levels for all channels

Status of alarms and warnings

System and machine operating condition

-

Time-Domain Measurements

RMS

Peak-to-Peak

AC+DC

DC Level

Real-time filtering and integration

Spectral Analysis

FFT with automatic DC component compensation

Overall calculation on user-defined frequency bands

Spectral mask comparison for anomaly detection

Order Analysis

Order tracking with amplitude and phase

Tachometer-based phase reference

Synchro Mode for cases with indirect tachometer reference

Order trends over time (up to four orders)

Acoustic Analysis

1/3-octave analysis for microphone sensors

Orbit Analysis (Eddy Current Sensors)

Orbit visualization (raw or order-based)

-

The post-processing module expands analysis capabilities with:

Polar plots for order analysis

Center Shaft Curve to evaluate shaft centerline shift

3D Waterfall and Sonogram displays (Time/RPM or Frequency/Orders)

Full Spectrum analysis (Forward/Reverse components)

Calculation of bearing characteristic frequencies based on construction parameters and speed

-

The software provides two recording formats, both of which can be active simultaneously:

1. Continuous Recording – BIN Format

High-frequency uninterrupted data logging

Ideal for detailed post-test analysis

2. Interval Recording – LOG Format

Data stored at predefined time intervals

Ideal for long-duration monitoring (hours or days)

Recording Trigger Modes

Manual activation by the operator

After a predefined time from acquisition start

Within a specific RPM range

When a parameter exceeds a configured threshold

-

A programmable reporting module allows the operator to:

Select metrics and analyses per channel

Generate layouts with one, two, or four graphs

Combine plots from different channels

Produce structured diagnostic reports automatically